In the suburbs of Lansing, MIwww.cechina.cn, far from the Pacific coast, there is a huge tank of salt water filled with many small creatures. Watching this tank, it is not uncommon to see a live shrimp flip into the air. But Andrew Wesolek just shrugs it off. He has seen startled shrimp before. “Yeah, they like to jump,” he notes. Wesolek oversees operations at Seafood Systems Inc., in Okemos MIwww.cechina.cn, one of America’s first indoor shrimp farms.

The plant is a pilot aquaculture R&D facility designed by comp

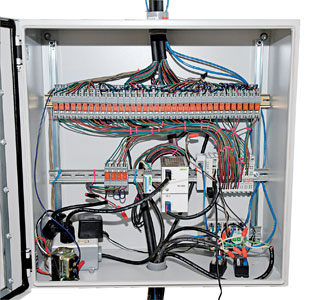

A Wago PLC has been programmed with a tailored shrimp feed curve that disperses food based upon variables such as stock in tank and growth state. Source: SSI

He transformed a pole-barn into the ideal space to grow, breed控制工程网版权所有, and harvest 10-limbed crustaceans. “We hope to revolutionize shrimp farming,” Wesolek adds. “The goal is to eventually produce 5 million pounds of shrimp per year out of a new控制工程网版权所有, larger facility.”

Most farmed shrimp consumed in the U.S. come from Pacific-rim nations and Central America, so there is a desire to develop domestic supplies.

10 legswww.cechina.cn, big appetites

Keeping the stock of Pacific white shrimp fed is a labor-intensive process that has to be repeated several times daily. “I used to manually feed them at least three times a day—every day,” Wesolek said.

And the amount has to be just right. Excess feed degrades water quality, but underfed shrimp mature slowly, taking them longer to become high-value deep-fried jumbo shrimp. Wesolek took on the task of creating an automated feeding process using a distributed control system. He wanted something sophisticated enough to do the job rightwww.cechina.cn, but was easy to program because he would be doing the work himsel

在线会议

在线会议 论坛

论坛 专题

专题 工控直播

工控直播 新闻中心

新闻中心 子站

子站 技术

技术 社区

社区

.jpg) 福禄克六大“法宝”帮您搞定过程仪表校准难题

福禄克六大“法宝”帮您搞定过程仪表校准难题 中控时间序列大模型TPT免费有奖体验

中控时间序列大模型TPT免费有奖体验 爱德克SE2L进阶版安全激光扫描仪有奖预约演示

爱德克SE2L进阶版安全激光扫描仪有奖预约演示 剑维软件电子半导体行业白皮书有奖下载

剑维软件电子半导体行业白皮书有奖下载 魏德米勒麒麟系列产品赋能本土工业

魏德米勒麒麟系列产品赋能本土工业